The sound of this much hammering is something not to be perceived if one has a choice- at least not after the first couple days of it. LOUD. I attached a pneumatic nailing hammer to a sixteen pound sledgehammer head with the handle cut short to help absorb the vibration and went to town. The result warped the bronze panels severely. I had them re-annealed, which flattened them again, but next time I’ll anticipate the need for the annealing. It is a cool experience- one buys good headphones and deals- and the product looks great.

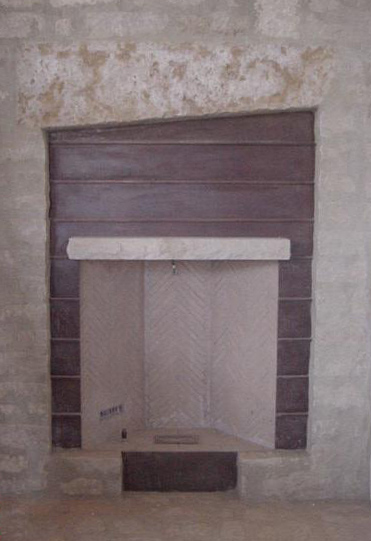

Thanks to the client I have decent pics of this fireplace. It seems to be aging nicely. I enjoy creative clients and designers willing to try new ways of doing things.

Photos of work that is lived with are so much better than construction shots. Thanks again, Dana!

After the panels and strips were hammered and annealled, I had a machinist blind tap the pieces and we screwed it all together, and then I patinated the whole thing all together.

After I had installed the bronze, the masons came and did the stonework. They did a nice job- it’s hard to see in this photo, but the sloped header is a single piece of stone.